What exactly is ABC?

Thermoplastic ABS is a popular material that is frequently used because of its excellent machinability, high impact strength, and good heat resistance. In spite of the fact that it is compatible with both 3D printing and CNC milling, the latter is going to be the primary focus of this article. Check out our other piece on ABS for a comprehensive guide to 3D printing.

ABS is an excellent choice for a wide variety of prototyping applications due to the properties it possesses as well as the low cost at which it can be obtained. More will be said about that at a later time.

How Does CNC Machining Work With ABS?

Because of its sturdy construction, the CNCJY Multitool 3D Printer is an excellent cnc milling online machine for working with plastics such as ABS. You have the option of using the CNC PRO milling toolhead to either cut or engrave ABS sheets, depending on the result that you are going for. Here are the steps:

Voxelizer Settings

You are free to select any milling speed between 1 and 15 mm/s for your project, provided that it is appropriate for the thickness of the ABS sheet you are using. It is important to avoid going in too deeply because the end mill may become clogged, which will cause the project to be unsuccessful.

Holding of the Workpiece

Another article has been written to provide a comprehensive instruction manual for holding workpieces. It's available for reading over here. In CNC milling, one of the most important considerations is how the material will be mounted. If the material is not securely fastened, the work will almost certainly be unsuccessful.

For mounting ABS sheets to the CNC worktable, you have the option of either utilizing the basic clamps that come packaged with the CNCJY Full Set or making use of a stron double-sided foam tape.

End Mills The end mills that are included with the CNCJY Full Set and the CNC Fun Pack that can be purchased from our online shop are able to be used for CNC machining ABS successfully.

Other

We strongly encourage you to use CNC milling with closed covers for your own protection.

Applications of the ABS

Although the versatile ABS plastic can be used for a wide variety of things, its primary function is that of a prototyping material. Casings, protective elements, and automotive components are some of the other popular applications for ABS.

Examples of Health and Safety Policies

ABS is a relatively risk-free material to work with, but you should be aware that when it is melted or burned, it releases fumes that could be hazardous to your health. Always make sure you are working in an area that has adequate ventilation, and if you start to feel lightheaded or your head starts to hurt, stop what you are doing, exit the room, and get some fresh air.

As always, we want to remind you to exercise extreme caution around the machine, particularly when it is operating. You run the risk of injuring yourself if you wear any articles of clothing that are too loose or have hair that is too long because it could get caught in the moving parts of the machine. When the machine is in operation, you should avoid touching any of the moving parts.

ABS: YOUR PROVEN, INTEGRATED MANUFACTURING PARTNER

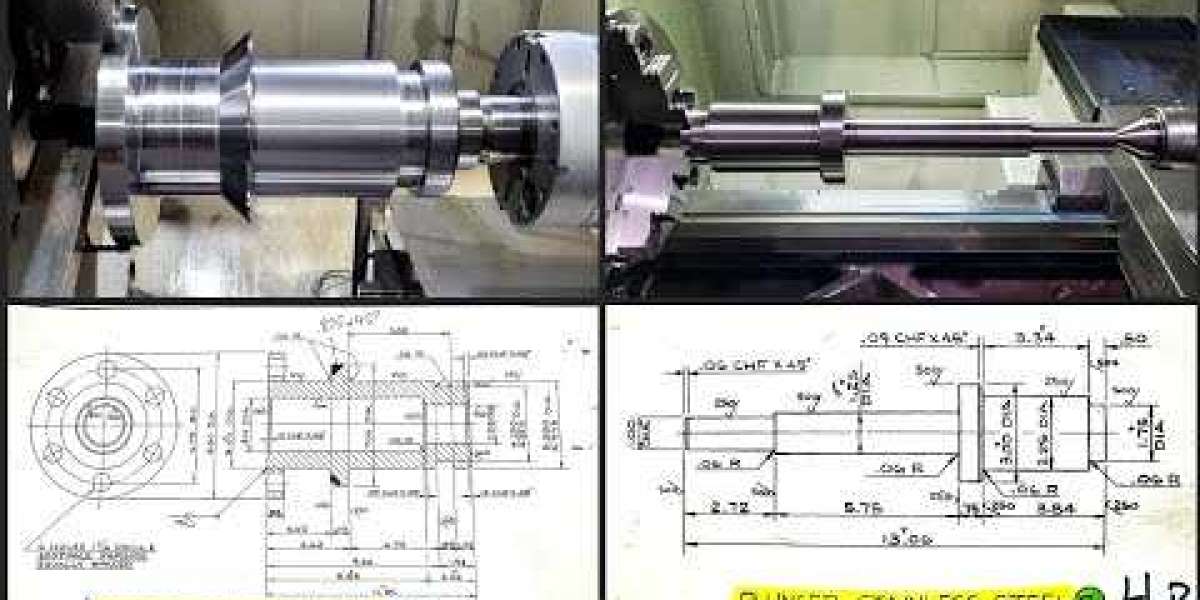

Integration is becoming an absolute requirement for original equipment manufacturers (OEMs) as the level of competition in the markets rises. As an integrated machine shop, ABS is able to provide our customers with a comprehensive manufacturing solution. Along the supply chain, we are responsible for a number of processes, including machining, heavy fabrication, welding, and assembly. Integrated manufacturers offer significant value to original equipment manufacturers (OEMs) by streamlining the manufacturing timeline, increasing the reliability of the final part, and minimizing the number of suppliers involved, all of which improve the supply chain's efficiency and reduce risks.

SPECIALISTS IN PRODUCTION MACHINERY for the United States of America

ABS builds a team of program managers and specialists dedicated to the successful management of each project from the very beginning of each and every program. This team then begins a collaborative review of all Quality, Manufacturing, and Engineering requirements from the very beginning of each program. Our in-process manufacturing team, in conjunction with our enterprise resource planning (ERP) and quality assurance department, works to guarantee complete client satisfaction. ABS has been recognized as a supplier for many critical components for decades, and the company continues to be awarded programs all over the world as a result of its unwavering dedication to quality, cost, and reliability.