Businesses can benefit in a variety of ways from the utilization of vertical carousels, one of which is the maximization of storage density. This can be accomplished by increasing the amount of available floor space. There are additional benefits, such as a boost in picking speed, an increase in picking accuracy, and an improvement in the ergonomics of the workplace.

Consider a common factory building, which typically has a ceiling that is ten meters (or thirty feet) high

If the warehouse in question makes use of static shelving for storage, then the height of the shelving units won't typically exceed ten feet on average

As a result of this, there is a space approximately 20 feet in height that is not being utilized above us

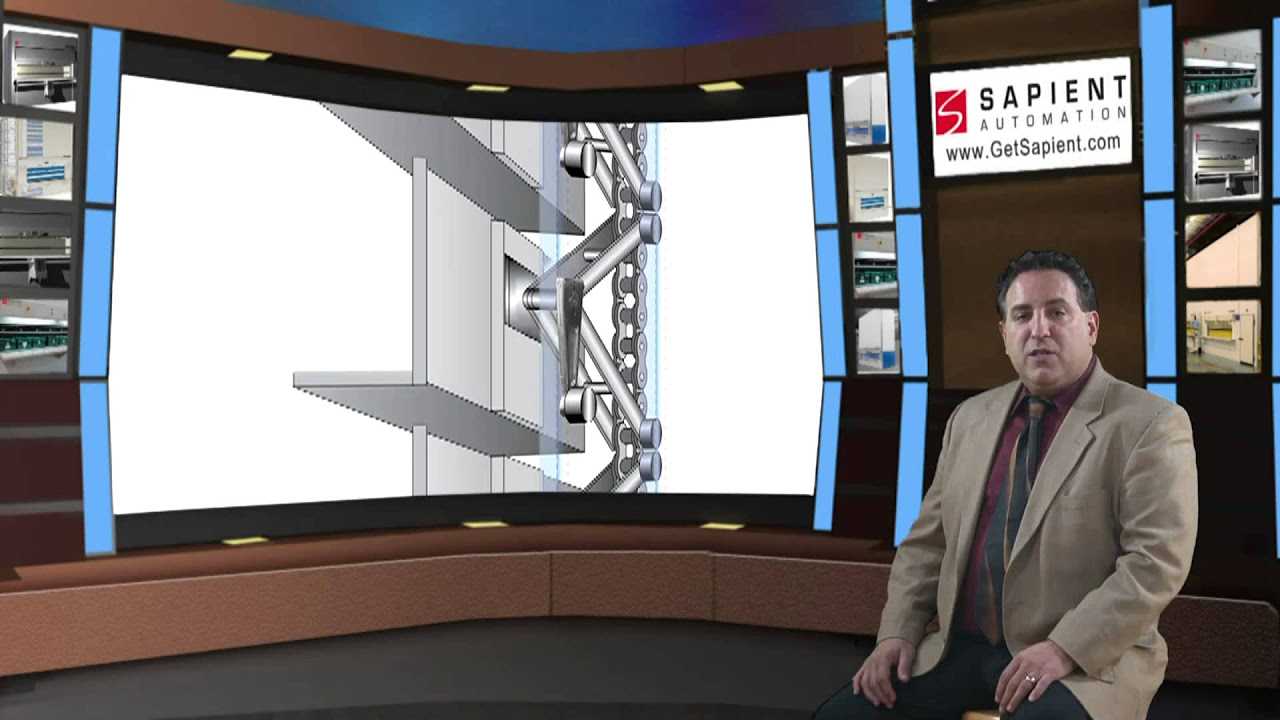

Vertical carousels make the most of this potential and increase storage capacity without substantially growing the required footprint on the warehouse floor

Vertical carousels are particularly useful in confined areas because they maximize storage density while also increasing the amount of available floor space. This makes them an excellent choice for vertical carousels. Consider the example of hospital pharmacies; on average, they take up about 2,000 square feet of space in the building. Not only is it necessary for pharmacies and technicians to conduct their work there, but also the storage of pharmaceuticals is mandated to take place in that particular location. White has been able to cut the amount of space that is required for storage in hospital pharmacies by at least fifty percent by installing vertical carousels in place of static shelving. This has enabled White to save space.

Vertical carousels allow for faster picking rates than traditional horizontal ones.

In warehouses where vertical used vertical carousel storage are utilized, it is not necessary for operators to walk from aisle to aisle in order to pick product. This makes the warehouse more efficient. Instead, the inventory is stored in the vertical carousel, and integrated computer software is used to call up the product of choice for delivery directly to the counter of the vertical carousel. This keeps the line moving quickly and efficiently. This results in the creation of a genuine automated storage and delivery system for the goods that are delivered to individuals.

A pick-to-light feature is also offered on white vertical carousel storage system as an alternative. This function illuminates on the counter and identifies the product that is supposed to be picked, the quantity that is required, as well as the part, serial, or stock number. In addition, it displays all of this information. After that, the operator will be able to select the product and then scan its bar code to ensure that they are selecting the appropriate product in the appropriate quantity at the appropriate time. As a direct result of this procedure, the picking speeds are accelerated by a sizeable amount. One of White's pharmacy's customers was able to reduce their pick times by a factor of fifty percent after the installation of our vertical carousel.(It is essential to keep in mind that the feature that allows you to put something on light can also be referred to as a tick bar.)

Vertical carousels improve both the speed and accuracy of picking as well as the management of inventory.

The pick-to-light function that is included in the White system directs the operator's attention to the container out of which they should be selecting items. In addition to this, it identifies the appropriate bin within the tote as well as the required amount of product to be placed within it. All of this is made conceivable as a result of technological advancements that allow for the retrieval of data from a computer that is a component of the vertical carousel. Accuracy in picking is of the utmost importance at all pharmacies, but especially those found in hospitals. Consider the situation of a pharmacist who is in charge of putting together a patient's medication schedule for the week. After the integrated software has been given the instruction as to which pills are required for each day, the vertical carousel will begin to rotate, and as it does so, it will present the correct medication to the operator, with pick-to-light indicating the appropriate tote, bin, and quantity for each item. This will take place as the vertical used vertical carousel continues to rotate.

When a pick is completed by an operator, the software that controls the vertical vertical carousel storage system may even be able to automatically reduce the quantity of that product that is currently in stock. This would be possible if the software was designed specifically for this purpose. White solutions make use of radiofrequency identification (RFID) tags, which are able to be attached to each individual product that is stored within the vertical carousel. These tags are read by the white solutions' vertical carousel readers. The operators are able to check the accuracy of each pick thanks to these tags. In addition to this, you can use them to monitor your inventory, track when products have passed their expiration dates, and track a variety of different incoming and outgoing processes.

Utilizing vertical parts carousel can provide one with ergonomically beneficial benefits.

The use of vertical lift machine has eliminated the need for workers to bend their knees or extend their arms in order to reach items stored on higher shelves. This is because operators of vertical carousel storage are presented with products at a counter that is 60 centimeters (40 inches) off the ground. This is the height that organizations from all over the world agree is best suited for a work source and which is recommended by those organizations. In addition, employees who work at used vertical carousel do not need to walk on the concrete floor of the warehouse, make use of a ladder, or operate machinery that is designed to lift people in order to access items that are stored on higher shelves. This is due to the fact that vertical carousel organize their inventory in a vertical fashion. These are the kinds of ergonomic benefits that contribute to increased levels of employee satisfaction, which in turn leads to increased levels of warehouse productivity.

The longevity and dependability of white, coupled with the numerous benefits it offers to businesses, equals a significant return on investment.

White vertical parts carousel are built to last, and we have a significant number of customers who are still making use of the systems that we designed, constructed, and installed for them more than 20 years ago. In addition to all of the benefits that have already been discussed, the longevity and dependability of that product contribute significantly to its return on investment (ROI), which is also significant. In other words, the total cost of a White automated storage solution is negligible in comparison to the savings that are possible due to improved warehouse performance when the cost of the solution is averaged out over the lifetime of the vertical carousel.